First Schnitzer Group TECHDAY

gets off to a charismatic start

Premiere! In early June, the first TECHDAY of the Schnitzer Group took place in Weissenburg, Bavaria. Organized by site manager Klaus Roessler and injection molding expert Joerg Woerrlein, the informal event offered an informative platform for networking, allowing participants to maintain and expand personal contacts. Exciting technical presentations and a special vehicle were the highlights under perfect summer weather!

Exciting presentations and distinguished guests

Selected industry representatives from the automotive sector, including suppliers, partners, and OEMs, accepted our invitation. The attractive “Kunststoffcampus Bavaria” in the Weissenburg Technology Center proved to be the perfect location for this event. Three captivating technical presentations were given on the topic "How design and function unite with new materials and technologies in the interior and exterior."

The following speakers generated great interest and encouraged intense discussions:

- Volker Gruendel (Trexel GmbH): Part design and Feasibility MuCell

- Martin Hahn (LEONHARD KURZ Stiftung & Co. KG): Fusion of charismatic design and function

- Tobias Posch (Porsche AG): A special insight into the creation of the Porsche 911 Dakar

Martin Hahn (Leonhard Kurz Stiftung & Co.KG), Tobias Posch (Porsche AG), Volker Gründel (Trexel GmbH), Klaus Roessler (Schnitzer Group, Local Manager Weissenburg)

From the subsequent discussions, three key focus areas emerged:

1. The Future of Product Design

The desire for aesthetics and individuality is increasingly changing product design. Additionally, an unprecedented transformation in design is taking place; surfaces are becoming seamless, and component geometries are increasingly organically shaped. User interfaces of electronic devices, control panels, and display modules are evolving. The incorporation of capacitive buttons and fully integrated touchscreens has already taken place intensively.

2. Integration of Functions

In this context, the integration of functions is a crucial aspect of these overall component requirements. Backlit symbols, front-end/rear-end systems, control displays and light management are becoming integral parts of the overall design. The creative use of ambient lighting is also gaining significant importance in automotive interiors and exteriors. "Light is the new chrome" – a frequently quoted phrase by designers that underscores the growing significance of light design.

3. Manufacturing Processes and Sustainability

Many questions revolve around the manufacturing of these novel components and the possible processes behind them. These approaches and possibilities were also presented and discussed in the technical presentations using application techniques and case studies. The fusion of new technologies and light design in the context of sustainability needs to be further explored. We look forward to future developments and technical implementations, not only in the automotive sector.

Many good conversations rounded off the afternoon with delicious snacks and drinks. That was TECHDAY 2024: a relaxed industry exchange at the technological cutting edge.

We look forward with great anticipation to the Schnitzer Group TECHDAY 2025!

Are you interested in participating in the next TECHDAY, have an exciting technical topic, or can you imagine speaking as a presenter? Simply contact us directly at: klaus.roessler@schnitzer-group.com

Until then, your Schnitzer Group Team

Impressions of the TECHDAY

Urban E-Mobility

Advances with the UPGRADER

The Schnitzer Group presents exciting news about the UPGRADER, our concept vehicle for urban e-mobility. Using an established 3D printing process, we have produced and successfully tested front panels and mounting elements. At the end of April, we completed a 125-kilometer endurance test that confirmed the quality and functionality of our developments. Minor optimizations are now underway, so stay tuned for further progress!

Stefan Mangold, Developer of the UPGRADER, on the 125 km endurance test

Dear Readers,

We are delighted to present you with the latest updates on our innovative mobility project, the UPGRADER.

3D Printing Processes for Customized Solutions

In the prototype phase, we have made remarkable progress. One example is the production and integration of our self-developed 3D-printed parts. For instance, we have manufactured the headlight front panels from PETG (polyethylene terephthalate glycol), a transparent yet robust material that is excellent for processing.

Additionally, mounting elements made from black PLA (polylactide) were developed to easily and securely fasten the aluminum tube support structures. This construction provides a stable base for attaching the selected flax panels, which are impressive due to their lightweight, sustainability and appealing design.

Flax Fiber Panel (Cladding) and 3D Printed Connecting Elements (Support Frame)

Successful Endurance Test – Quality and Functionality Confirmed

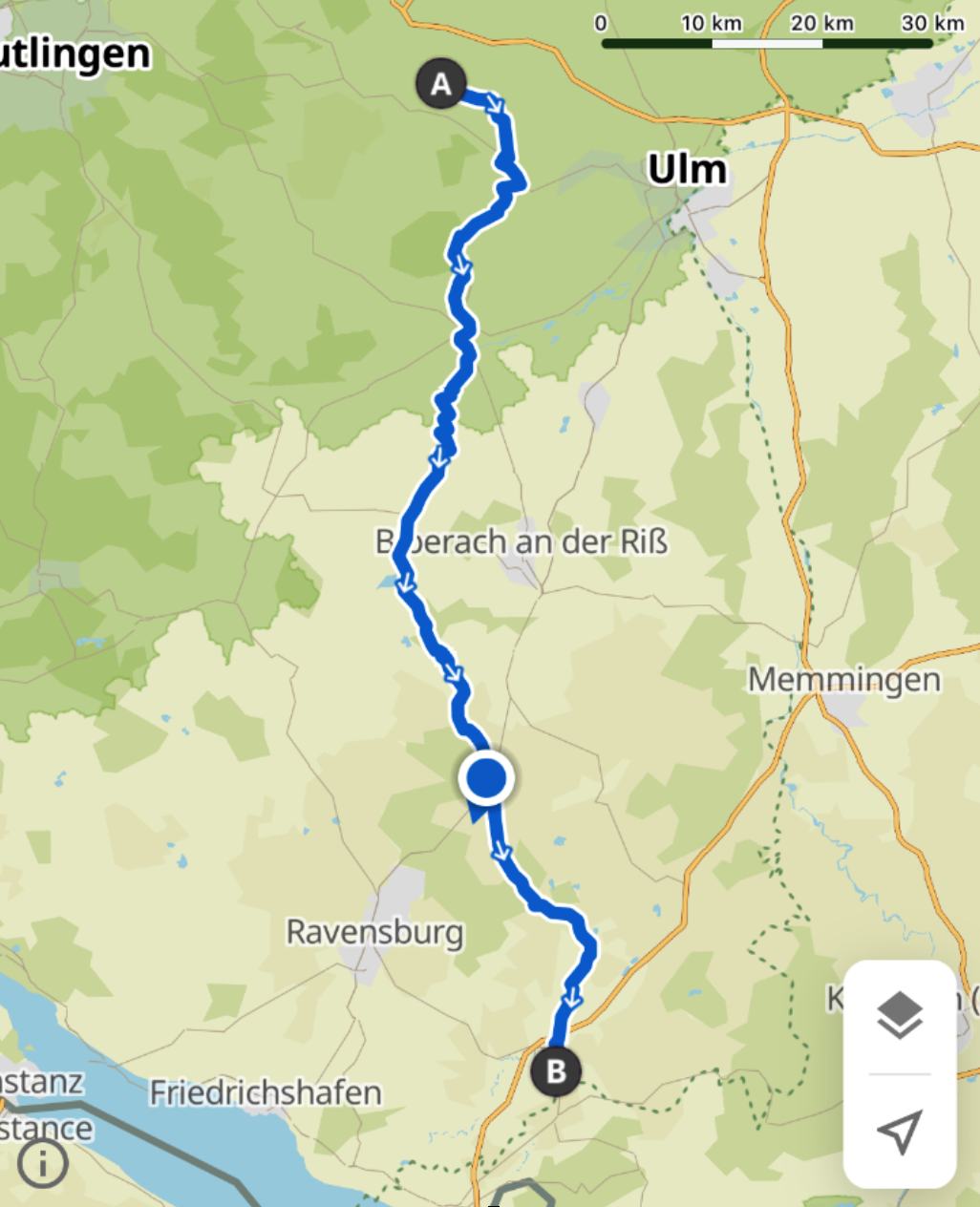

At the end of April 2024, a critical 125-kilometer endurance test was on the agenda. The goal was to test the technical properties and quality of the printed parts. After a 10-hour trip from Laichingen to Wangen im Allgaeu (South Germany), our team was pleased to note that the functionality and quality of the 3D-printed components, as well as the UPGRADER overall, met the high expectations. No safety-related issues occurred.

Route of the 125 km Test Drive

Continuous Optimization in Focus

As is common in the prototype phase, minor optimization potentials were identified. We will address these in the coming weeks to further improve the UPGRADER and expand our knowledge of urban electric mobility systems.

We thank you for your interest and support. Stay tuned for the next advancements in the development of the UPGRADER. Together, we are shaping the future of urban mobility.

Your Schnitzer Group Team

Patrick Heine, Project Support/Marketing (left)

Taulant Shala, Design and Execution of 3D Printed Components

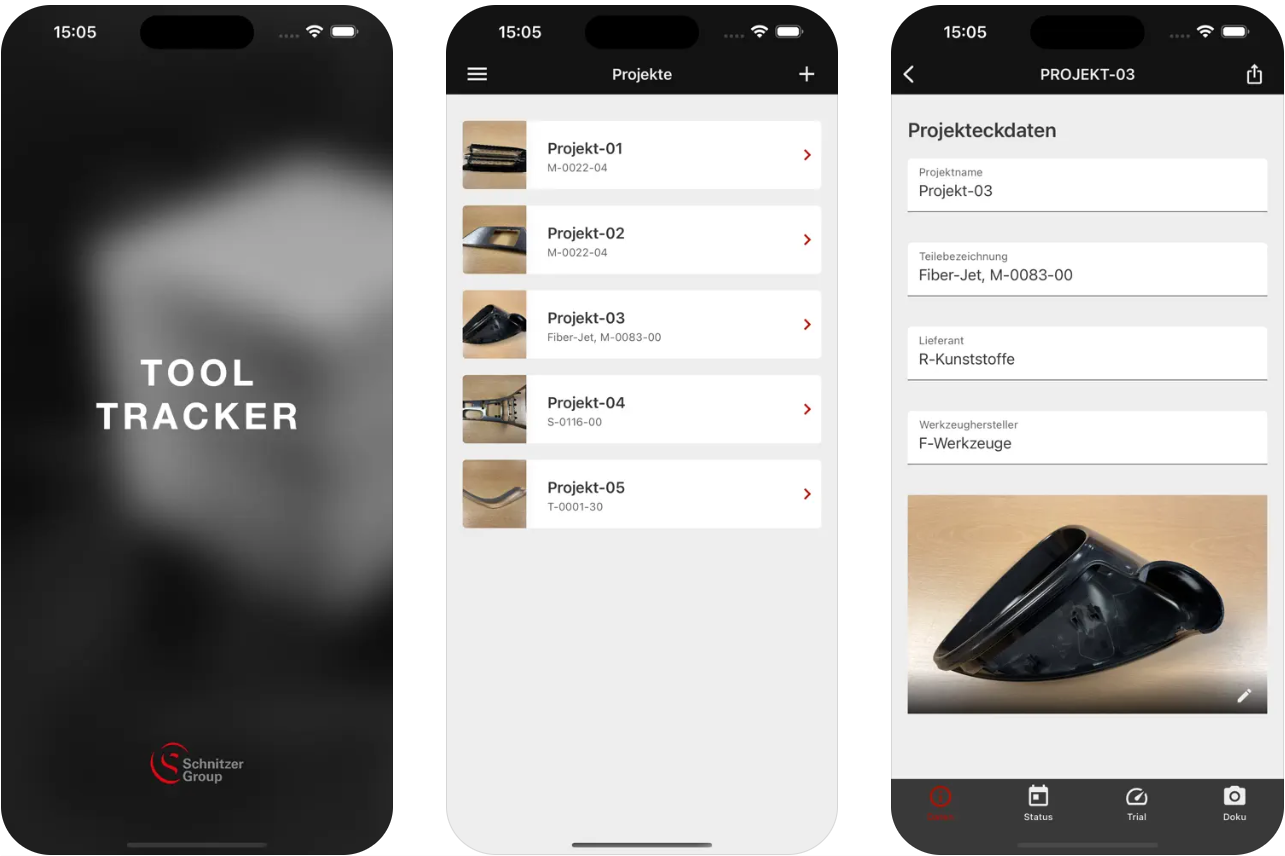

Schnitzer Group Tool Tracker App

Free Update Available!

The Schnitzer Group has developed digital "helpers" for daily technical project work. The latest highlight is the updated Tool Tracker App. It simplifies processes, increases transparency and can be used for project documentation. Our Tool Tracker App is suitable for toolmakers, project managers, purchasers, and quality control personnel across all industries.

Track Tool Status: Fast, Clear, Easy. In a short time, the Tool Tracker provides an overview for tool scheduling management. Detailed with photo documentation and deadline monitoring (planned/actual dates), the Tool Tracker monitors tool production from design to approval.

Those dealing frequently with tool approvals and sampling will quickly appreciate the functionality of our updated reporting app.

What's New? (12 Mar 2024 Version 1.4.4)

- Available in German and English

- Integrated sampling documentation

- Calendar week calculator integrated

Special Features:

- 5-color status gauge

- Free-text options for current processing status

- Free-text fields for recommendations and current status

- Direct photo capture or import from gallery

- Reports in Excel format - exportable via email from mobile devices

Download Link: Schnitzer Group App (schnitzer-group.com)

Give it a try!